Savonius Rotor

Overview

The Savonius or S-rotor is certainly one of the simplest wind machines and a favorite of home inventors. It is often made from round metal drums or cans that are cut in half and then slightly offset to create scoops that drag on the wind. By stacking several of these S-shapes on top of each other, you can increase the torque of the machine. Since it is a vertical axis machine, it operates with wind from any direction. It is rather inefficient, but like other drag-type devices, it will operate in light winds. Sometimes Savonius rotors are used to start other vertical axis machines (such as Darrius wind turbines) that have aerodynamic blades and are not self-starting.

Build this model to gain some experience with Savonius rotors and then try building a larger machine of your own design.

MATERIALS

40" of 1/2" plastic pipe

4) 3/4" Plastic elbows

1) 3/4" Plastic T

1) 1 " Plastic cap

4) Pop cans or equivalent sheet metal

12" of 3/8" dowel

16" x 8" of 1/4" plywood

Staples and hot glue

INSTRUCTIONS

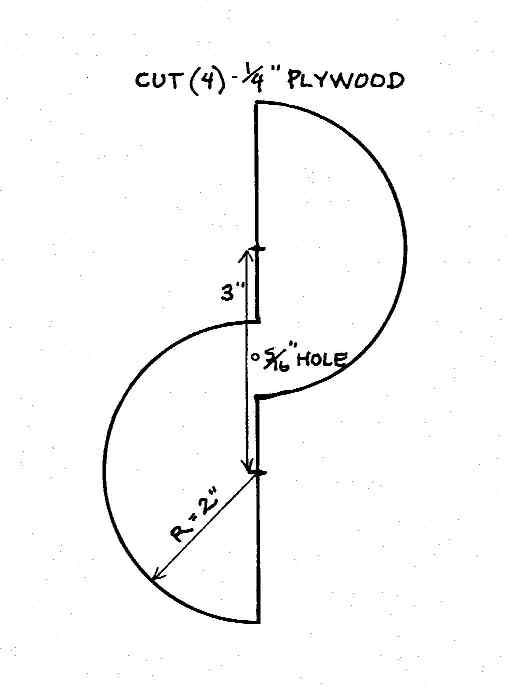

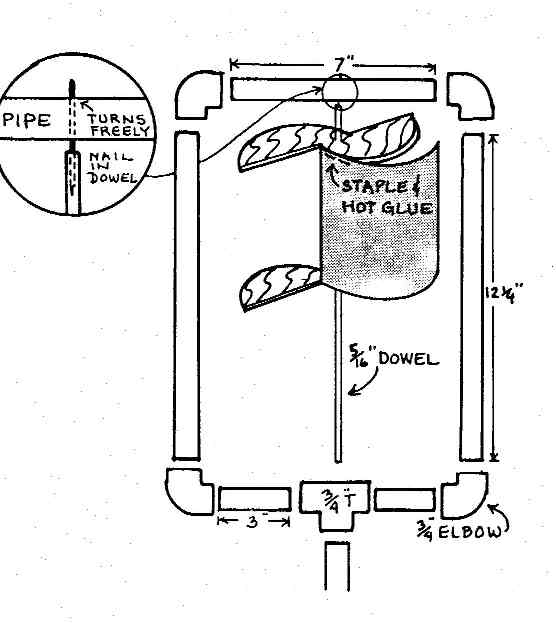

1) Cut plywood pieces according to plans; -drill 3/8" hole. Slide forms on dowel.

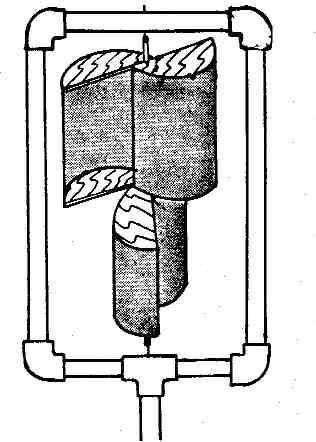

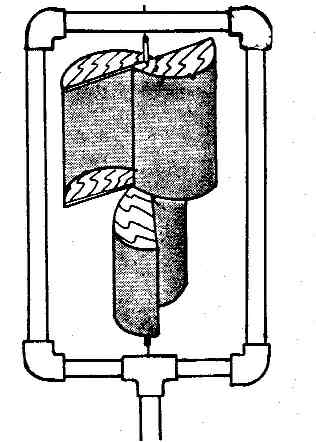

2) Cut cans or sheet metal to prescribed sizes and fold one edge to make a 1/4" lip. Attach the aluminum to the forms with hot glue and staples. Start at the center and work outward.

3) Cut and assemble the plastic frame with cement but leave the top elbows unglued. Cut a hole in the 1 " cap and glue the T into place so that the frame can be mounted on a 1" tower. Otherwise simply mount the frame on a 3/4" plastic pipe.

4) Drill the ends of the dowel and set a headless nail in it to act as a pivot point. Drill the top and bottom of the mounting frame to accomodate the rotor. Put rotor in place and slide the top of the frame down, locking it there. Twist the two rotors so that they contact the wind at different angles. A wooden pulley could be glued directly on the dowel to power some other device.